Power transformers serve as the backbone of electrical distribution systems, enabling efficient voltage regulation across diverse network configurations. Within these critical components, the tap changer mechanism plays an essential role in maintaining optimal voltage levels under varying load conditions. Modern electrical infrastructure demands precise voltage control to ensure system stability, equipment protection, and energy efficiency. Understanding the operational principles and technical specifications of tap changer systems becomes increasingly important as power grids evolve toward smart grid technologies and renewable energy integration.

Fundamental Principles of Tap Changer Operation

Voltage Regulation Mechanisms

The primary function of a tap changer involves adjusting transformer turns ratios to maintain consistent output voltage despite fluctuations in input voltage or load conditions. This mechanism operates by connecting different tapping points along the transformer winding, effectively changing the number of active turns in the circuit. When input voltage increases beyond acceptable limits, the tap changer automatically selects a higher tap position, reducing the turns ratio and consequently lowering the output voltage to desired levels.

Advanced tap changer systems incorporate sophisticated control algorithms that monitor voltage variations in real-time, ensuring rapid response to grid fluctuations. These systems typically feature multiple tapping positions, ranging from five to thirty-three steps depending on application requirements and voltage regulation precision needs. The selection of appropriate tap positions depends on factors including load characteristics, network impedance, and regulatory voltage standards established by utility companies.

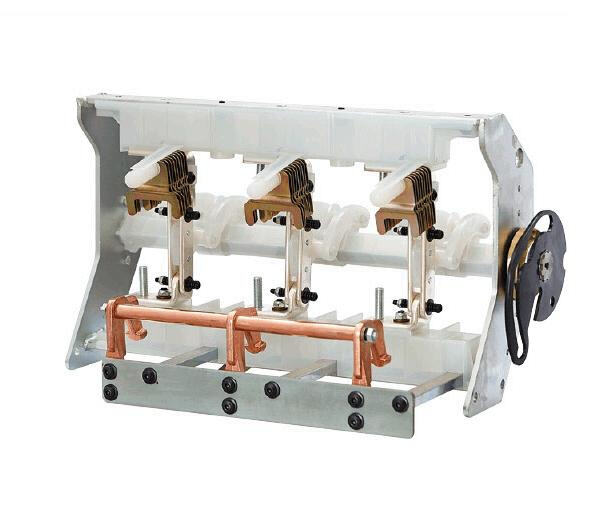

Electrical Contact Systems

Modern tap changer designs utilize various contact technologies to ensure reliable switching operations under load conditions. Vacuum interrupters represent the most advanced solution, providing arc-free switching capabilities and extended operational lifespans compared to traditional oil-immersed contact systems. These vacuum-based systems eliminate the risk of carbon formation and reduce maintenance requirements significantly.

Alternative contact configurations include resistor-type tap changers that employ transition resistors during switching operations to limit circulating currents and minimize arcing effects. The resistor insertion process occurs automatically during tap transitions, protecting both the transformer windings and the switching mechanism from excessive electrical stress. This technology proves particularly effective in high-voltage applications where switching currents can reach substantial levels.

Load Tap Changer Classifications and Applications

On-Load Versus Off-Load Operations

Load tap changers divide into two primary categories based on their operational capabilities during energized conditions. On-load tap changers, also known as load tap changers, can perform switching operations while the transformer remains connected to the electrical system and carries load current. This capability proves essential for maintaining continuous power supply during voltage adjustment procedures, particularly in critical industrial and commercial applications.

Off-load tap changers require complete de-energization of the transformer before any tap position changes can occur. While these systems offer lower initial costs and simplified maintenance procedures, they cannot provide real-time voltage regulation capabilities. Off-load configurations find application in distribution transformers serving non-critical loads where temporary power interruptions during maintenance operations remain acceptable.

Automatic Voltage Control Systems

Modern tap changer installations incorporate automatic voltage regulators that continuously monitor system parameters and initiate tap changes based on predetermined control algorithms. These systems feature programmable voltage set points, time delays, and bandwidth settings that optimize switching frequency while maintaining voltage stability within acceptable tolerance bands.

Advanced control systems integrate communication protocols enabling remote monitoring and control capabilities through supervisory control and data acquisition systems. This connectivity allows utility operators to adjust voltage regulation parameters, monitor tap changer performance, and schedule maintenance activities based on real-time operational data. Integration with smart grid infrastructure enhances system-wide voltage optimization and power quality management capabilities.

Technical Design Considerations and Components

Mechanical Drive Mechanisms

The mechanical drive system represents a critical component responsible for physically moving the tap changer selector switch between different tapping positions. Motor-driven mechanisms utilize precision gear trains and clutch assemblies to ensure accurate positioning and reliable operation under various environmental conditions. These systems incorporate position feedback sensors that verify correct tap selection and prevent operation outside predetermined limits.

Manual drive options remain available for applications requiring simplified operation and reduced complexity. These mechanisms feature mechanical indicators showing current tap positions and include safety interlocks preventing unauthorized or accidental operation. Manual systems prove particularly suitable for distribution transformers in rural applications where automatic voltage regulation may not justify additional equipment costs.

Insulation and Environmental Protection

Proper insulation design ensures reliable tap changer operation across varying voltage levels and environmental conditions. Oil-immersed designs utilize high-quality insulating oil that provides both electrical insulation and cooling for internal components. The oil medium also serves as an arc-quenching agent during switching operations, extending contact life and reducing maintenance requirements.

Sealed tank constructions prevent moisture ingress and contamination that could compromise insulation performance over time. Advanced sealing systems incorporate nitrogen blanketing or conservator tanks with silica gel breathing systems to maintain optimal oil conditions throughout the operational lifespan. Temperature monitoring systems track oil and winding temperatures, providing early warning indicators for potential thermal issues.

Installation and Maintenance Requirements

Commissioning Procedures

Proper commissioning of tap changer systems requires comprehensive testing protocols that verify mechanical operation, electrical performance, and control system functionality. Initial testing procedures include measurement of contact resistance across all tap positions, verification of insulation levels, and validation of automatic control system responses. These tests establish baseline performance parameters for ongoing maintenance programs.

Field testing protocols also encompass verification of protection system coordination, ensuring that tap changer operations do not interfere with upstream or downstream protective devices. Proper coordination prevents nuisance tripping and maintains system stability during normal voltage regulation activities. Documentation of all test results provides essential reference data for future maintenance and troubleshooting activities.

Preventive Maintenance Strategies

Effective maintenance programs for tap changer systems focus on regular inspection of mechanical components, oil quality analysis, and electrical contact condition assessment. Scheduled maintenance intervals depend on operating frequency, environmental conditions, and manufacturer recommendations. High-frequency operation environments may require more frequent inspections to ensure continued reliability.

Oil analysis programs monitor key parameters including dielectric strength, moisture content, and dissolved gas concentrations that indicate potential internal problems. Trending these parameters over time enables predictive maintenance approaches that identify developing issues before they result in equipment failures. Regular oil filtration and replacement maintain optimal insulating properties and extend overall system life.

Performance Optimization and Troubleshooting

Operational Parameters and Monitoring

Optimal tap changer performance requires careful attention to operational parameters including switching frequency, voltage deviation limits, and response time characteristics. Excessive switching frequency can accelerate contact wear and reduce overall system reliability, while insufficient response may result in voltage regulation outside acceptable limits. Proper parameter adjustment balances these competing requirements based on specific application needs.

Modern monitoring systems provide real-time visibility into tap changer operations through comprehensive data logging and alarm functions. These systems track switching operations, motor current consumption, and environmental conditions that affect performance. Historical data analysis reveals trends and patterns that support optimized maintenance scheduling and operational adjustments.

Common Issues and Solutions

Typical tap changer problems include mechanical binding, contact deterioration, and control system malfunctions that can compromise voltage regulation capabilities. Mechanical issues often result from inadequate lubrication, misalignment, or wear of drive components that prevent smooth operation between tap positions. Regular inspection and lubrication procedures address most mechanical concerns before they impact system performance.

Electrical contact problems manifest as increased resistance, arcing during switching operations, or complete failure to establish reliable connections. These issues typically require contact replacement or reconditioning procedures that restore proper electrical performance. Advanced diagnostic techniques including resistance measurements and thermal imaging help identify developing contact problems during routine maintenance activities.

FAQ

What is the typical lifespan of a tap changer system?

A properly maintained tap changer system typically operates reliably for 25 to 30 years, with some installations exceeding 40 years of service life. The actual lifespan depends on factors including operating frequency, environmental conditions, maintenance quality, and original equipment specifications. High-quality systems with regular maintenance programs consistently achieve longer operational lifespans compared to installations with deferred maintenance practices.

How often should tap changer oil be analyzed and replaced?

Oil analysis should be performed annually for most tap changer installations, with more frequent testing recommended for high-frequency operation environments or critical applications. Complete oil replacement intervals typically range from 10 to 15 years, depending on analysis results and operational conditions. Emergency oil replacement may be necessary if analysis reveals significant degradation in dielectric strength or excessive moisture content that could compromise system reliability.

Can tap changers be retrofitted with automatic control systems?

Most existing manual tap changer installations can be upgraded with automatic voltage control systems through retrofit packages that include motor drives, control panels, and sensing equipment. These upgrades typically require evaluation of existing mechanical components to ensure compatibility with automated operation. Professional engineering assessment determines the feasibility and cost-effectiveness of retrofit installations compared to complete system replacement alternatives.

What safety precautions are required during tap changer maintenance?

Tap changer maintenance requires complete de-energization of the transformer, proper lockout and tagout procedures, and verification of zero energy state before beginning work activities. Personnel must use appropriate personal protective equipment and follow established safety protocols for working around high-voltage equipment. Confined space entry procedures may be necessary for internal inspections of tank-mounted systems, requiring additional safety precautions and atmospheric monitoring.