oil immersed distribution transformer

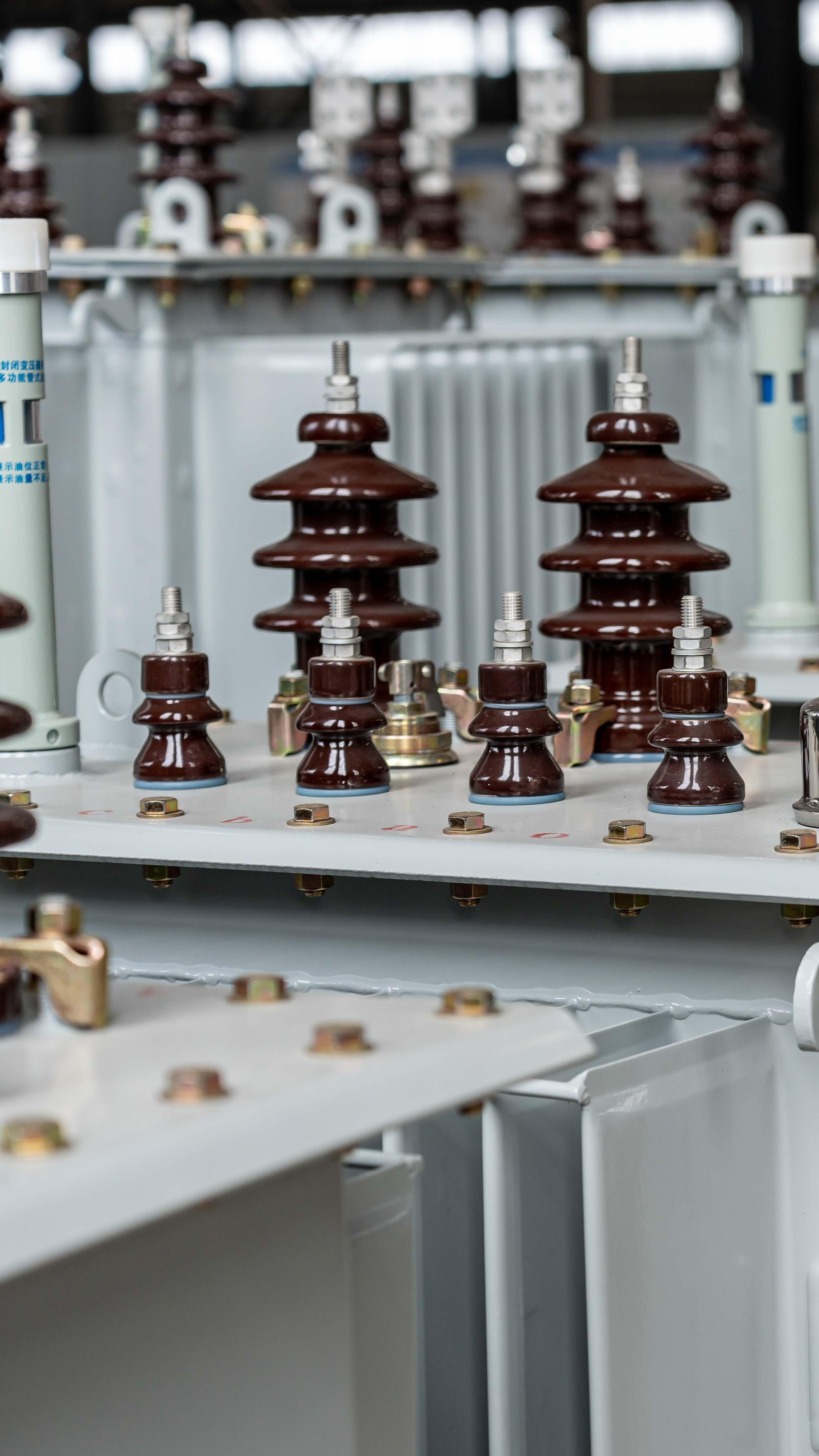

The oil immersed distribution transformer represents a crucial component in electrical power distribution systems, engineered to efficiently convert high voltage electricity to lower, more usable voltage levels. This sophisticated piece of equipment utilizes insulating oil as both a cooling medium and electrical insulator, ensuring optimal performance and longevity. The transformer's core and windings are completely submerged in specially formulated mineral oil, which serves multiple critical functions. The oil effectively dissipates heat generated during operation, prevents oxidation of internal components, and provides superior electrical insulation. These transformers are designed with robust tanks, radiators for enhanced cooling, and sophisticated monitoring systems to maintain optimal oil levels and temperature. They come equipped with various safety features including pressure relief devices, oil level indicators, and temperature gauges. The technology accommodates different power ratings, typically ranging from 50 kVA to 2500 kVA, making them suitable for various applications from residential areas to industrial complexes. Their design incorporates advanced core materials and winding arrangements that minimize energy losses and ensure high operational efficiency.