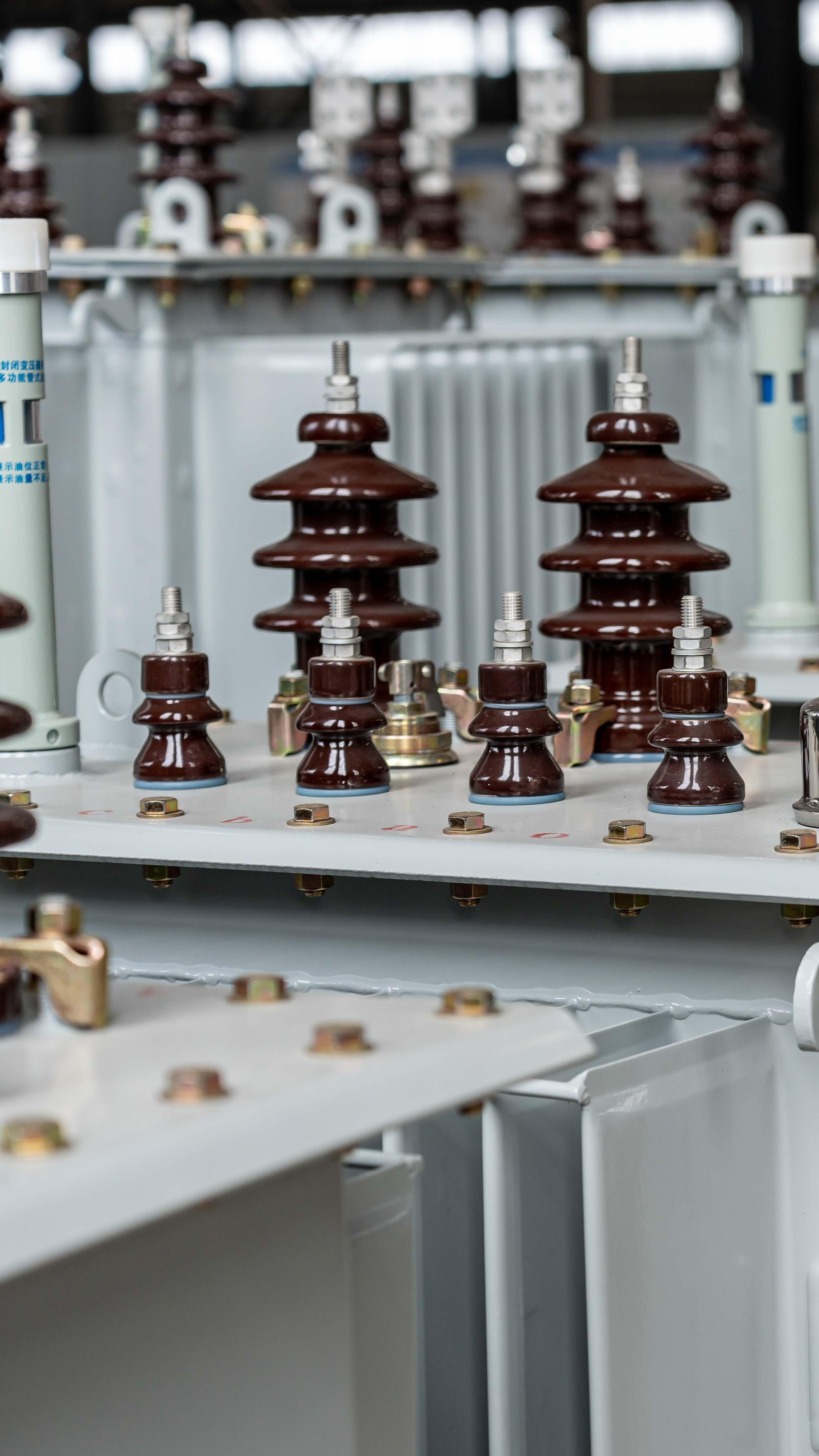

oil immersed transformer

An oil immersed transformer represents a critical component in electrical power systems, designed to transfer electrical energy between circuits through electromagnetic induction. This sophisticated device uses mineral oil as both a cooling medium and electrical insulator, enabling efficient operation at high voltage levels. The transformer's core and windings are completely submerged in specially refined mineral oil, which serves multiple essential functions. The oil effectively dissipates heat generated during operation, maintains consistent internal temperatures, and provides superior electrical insulation properties. These transformers are engineered with robust tanks, radiators for heat exchange, and sophisticated monitoring systems to ensure optimal performance. They come equipped with expansion tanks to accommodate oil volume changes due to temperature fluctuations, conservators to prevent oil oxidation, and various safety devices including pressure relief valves and Buchholz relays. The design allows for operation across a wide range of voltage levels, from distribution networks to high-voltage transmission systems. Their application spans across various sectors, including power generation plants, industrial facilities, and utility substations, making them fundamental to modern electrical infrastructure.