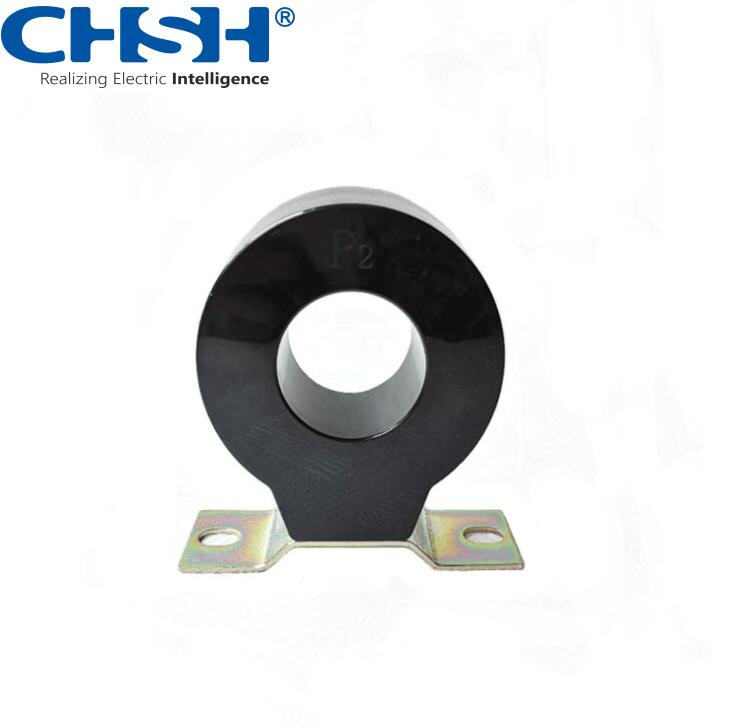

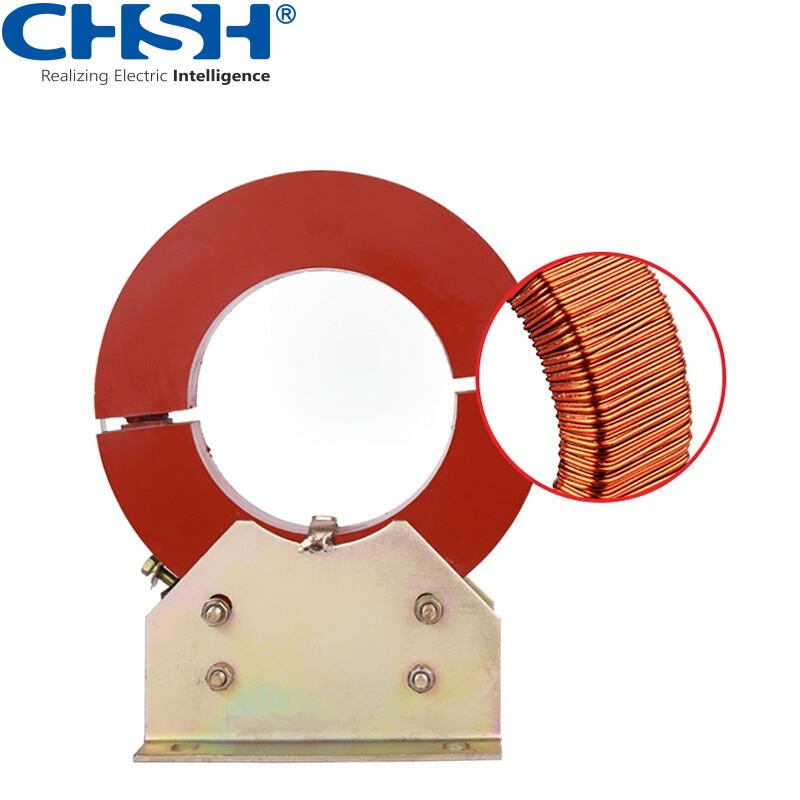

direct current transformer

A direct current transformer is a sophisticated power electronics device designed to convert one DC voltage level to another. Operating through advanced switching technology and electromagnetic principles, these transformers play a crucial role in modern power distribution systems. Unlike traditional transformers that work with alternating current, DC transformers utilize high-frequency switching techniques to achieve voltage transformation. The device consists of primary and secondary windings wrapped around a ferrite core, complemented by power semiconductor switches and control circuits. These components work in harmony to first convert DC to high-frequency AC, transform the voltage level, and then rectify it back to DC. The transformer's ability to maintain stable output voltage despite input fluctuations makes it indispensable in various applications, from renewable energy systems to electric vehicle charging stations. Modern DC transformers incorporate advanced features such as galvanic isolation, which enhances safety by preventing direct electrical connections between input and output circuits. They also employ sophisticated control algorithms to optimize efficiency and respond rapidly to load changes. The technology finds extensive use in solar power systems, data centers, telecommunications equipment, and industrial automation, where reliable DC power conversion is essential.