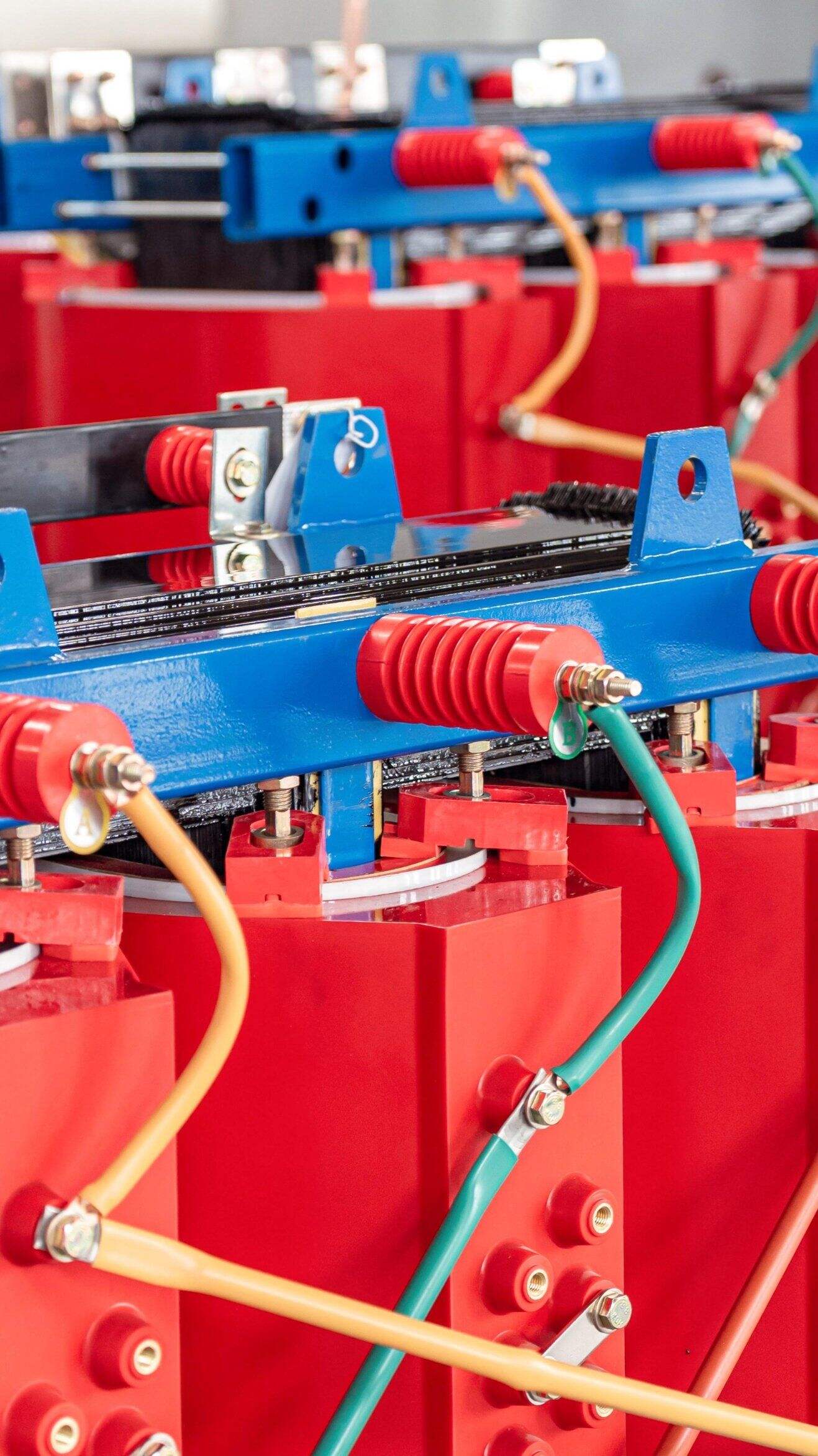

3-fase tørrtype transformator

En trefaset tørrtransformator er en viktig elektrisk enhet som er designet for å effektivt overføre elektrisk energi mellom kretser gjennom elektromagnetisk induksjon, uten bruk av væskeisolasjon. Disse transformatorene fungerer ved å konvertere spenningsnivåer mens de opprettholder samme frekvens, noe som gjør dem avgjørende for kraftforsyningssystemer. Kjernekonstruksjonen består av tre sett med primære og sekundære viklinger montert på en kjerne av silisiumstål, og bruker isolasjonsmaterialer av høy kvalitet som epoksyhars for forbedret ytelse. I motsetning til oljefylte transformatorer bruker tørrtransformatorer luft som kjølemiddel, noe som gjør dem miljøvennlige og sikrere for innendørs installasjoner. Transformatorens design inneholder avanserte varmemanagement-systemer som sikrer optimal drift under ulike belastningsforhold. Disse enhetene er produsert med isolasjonssystemer i klasse F eller H, og klarer temperaturer opp til henholdsvis 155°C og 180°C. Moderne trefaset tørrtransformatorer har sofistikerte overvåkningssystemer for temperaturkontroll, spenningsregulering og beskyttelse mot overbelastning, og sikrer dermed pålitelig drift og lang levetid. De er spesielt egnet for kommersielle bygninger, industrielle anlegg og byinstallasjoner der brannsikkerhet og miljøhensyn er av største viktighet.